Case Study - Raising the standard of MedTech Automation via disruptive Catheter Reflow System

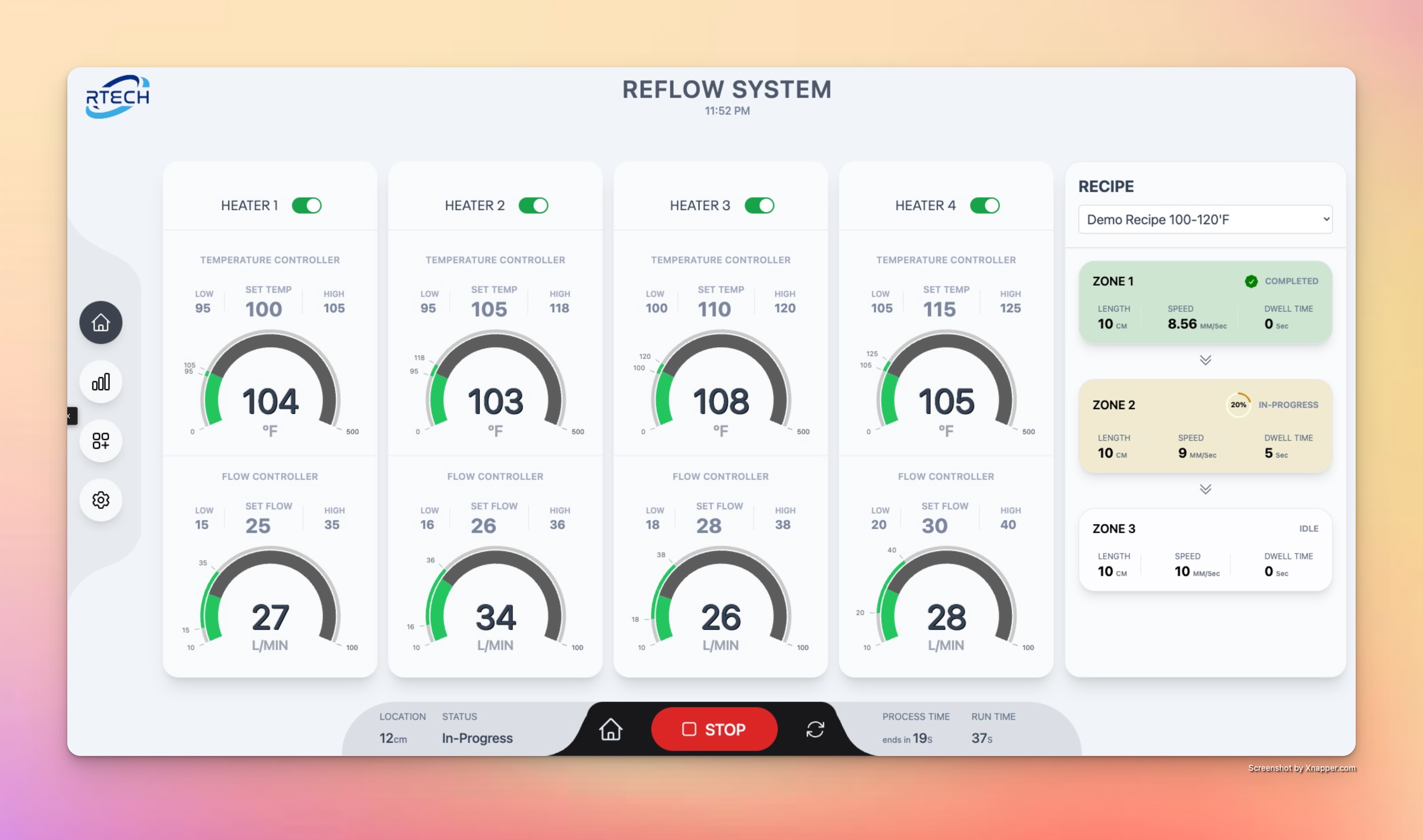

As a provider of cutting-edge Automation Solutions for Smarter Manufacturing, RTECH, Inc. equips MedTech device manufacturers with the tools they need to excel. To maintain their competitive edge and offer truly next-generation capabilities, RTECH needed a sophisticated and flexible control system for their catheter reflow automation packages – one that would surpass the limitations of typical industry offerings and potentially disrupt established automation competitors. We partnered with RTECH to build that core differentiator.

- Client

- RTECH, Inc

- Industry

- Manufacturing, MedTech

- Services

- Custom Application Development, Hardware Integration, GUI Design

The Challenge: Legacy Controls Stifled RTECH's Edge.

Off-the-shelf controllers couldn't give RTECH's MedTech clients the flexibility or data they needed. Relying on outdated, closed systems choked innovation and put RTECH at a competitive disadvantage. They needed a modern control core to deliver:

- Total process freedom, ditching rigid presets.

- Built-in quality assurance with real-time data.

- Seamless integration without proprietary lock-in.

- Effortless scalability for future growth.

Our Fix: A Custom Control Engine for RTECH's Win.

We built the intelligent heart RTECH needed—a powerful, bespoke touch application. This gave RTECH a decisive market advantage, letting them offer their clients:

- Unleashed Process Design: Unlimited recipes mean total control for RTECH's customers.

- Guaranteed Quality: Real-time data & alarms ensure rock-solid process integrity.

- Seamless Hardware Integration: Flawless connection to best-in-class components (Watlow, Alicat, Zaber). No compromises.

- Deploy Anywhere Flexibility: Run on Win, Mac, Linux, or SBCs – maximum freedom, zero lock-in.

- Built-in Scalability: Configure up to 10 Temperature & Flow controller on the fly. Ready for anything.

How We Delivered RTECH's Advantage.

Our end-to-end expertise forged RTECH's technological edge:

Intuitive GUI Design: Crafting interfaces MedTech operators find efficient and easy to use. Robust Custom Development: Building the flexible, reliable software engine RTECH couldn't find elsewhere. Expert Hardware Integration: Making sophisticated hardware components work together, flawlessly.

What we did

- GUI Design

- Custom Application Development

- Hardware Integration